Next-Generation Flooring Technology

The Science of Mineral Silicate

Discover how ancient volcanic chemistry meets modern innovation to create sustainable, high-performance flooring solutions.

What is mineral silicate binder?

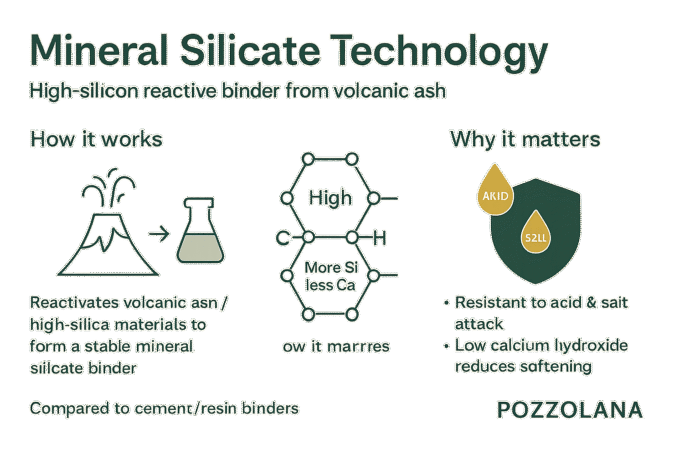

Pozzolana mineral silicate binder is formed by reactivating pozzolanic raw materials of high silicon content to create an exceptionally stable binding system which can overcome almost all of the weaknesses of cement and resin-based binders while simultaneously gaining additional properties and benefits.

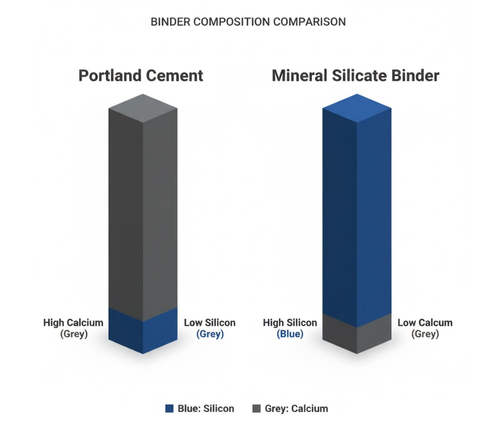

It contains much more silicon and much less calcium than cement. The high content of calcium hydroxide in hydrated cement is highly susceptible to chemical attack, causing cement mortar or concrete to deteriorate. Whereas hydrated mineral silicate binder contains much higher amounts of Calcium Silicate Hydrate (CSH) which is a very stable element.

Mineral silicate is a much more environmentally friendly alternative to conventional cement for non-structural use. It is made by simple blending process of volcanic-based natural materials and industrial byproducts to significantly reduce the carbon footprint when compared to cement production, while also being highly resistant to many chemical compounds.

Composition of Binders

Si+ (Silicon)

Ca+ (Calcium)

Environmental Impact

Reducing Carbon Emissions

Traditional cement production is one of the largest sources of CO₂ emissions globally. Our mineral silicate technology dramatically changes this equation.

1 ton CO₂

Traditional Cement

1 ton cement = 1 ton CO₂ emissions

~0.1 ton CO₂

Pozzolana Binder

Up to 90% less CO₂ emissions

90%

reduction in CO₂ emissions with Pozzolana binder systems

How It Works

Technology Inside

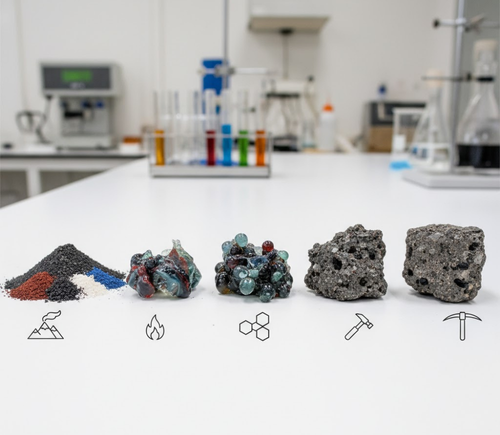

Utilizing latent hydraulic and pozzolanic raw materials which are accrued during different industrial processes and activating them chemically.

Use silicate-based materials that have a high Si⁺ content

GGBS

Volcano Ash

Pumice

Kaolin

Fly Ash

Silica Powder

A

Activator

H₂O

The reaction which creates the final product follows the cycle of rock formation in nature

Incomplete Melting

Initial material preparation

Recrystalli-zation

Molecular restructuring

Fractional Crystalliza-tion

Accelerated reactions

Weathering

Absorbs gases, salts, CO₂

Rock Formation

Slowly becomes harder

100% Inorganic

High Corrosion Resistant

Stable with Temperatures

Cement-Free

Resin-Free

The Science

Chemistry of Mineral Silicate

Si

O

O

O

O

Silicate

SiO2

H

O

Ca

O

H

Calcium Hydroxide

Ca(OH)2

Ca · Ca · Ca

Si-O-Si-O-Si

Ca · Ca · Ca

H₂O

Calcium Silicate Hydrate

C-S-H Crystals

Ca(OH)₂ reacts with silicates and forms highly stable calcium silicate hydrate crystals (CSH-phases). These crystals create an exceptionally durable matrix that resists chemical attack and environmental degradation.

Why Choose Pozzolana

Mineral Silicate Advantages

Human-safe chemistry and minimal environmental impact, paired with strong performance.

VOC and APEO Free

Minimize the effects to human health and environment with zero volatile organic compounds.

Application by Machines

Can be applied with a variety of machines for floors and walls efficiently.

Apply to Many Substrates

Can be applied on weak, moist, calcium sulphate and magnesium carbonate substrates.

Chemical, Salt Resistant

Stable in many high chemicals or salt environments without degradation.

Burnishable & Polishable

Can be burnished or polished to get more shiny, reflective surfaces.

Stable with Temperatures

Can be used in wide range of temperature environments or thermal shocks.

Flexible in Application

Can be transformed to many kinds of application to follow requirements.

Easy Pigmentation

Can be easily colored by powder or liquid pigments to create bright colors.

Conventional Issues Solved

Problems We Have Avoided

Traditional flooring materials come with significant drawbacks. Here's what you won't experience with Pozzolana.

No Shrinkage

Cracks due to shrinkage do not occur, maintaining surface integrity over time.

No Joints

No saw-cut joints required on stable substrates, creating seamless surfaces.

No VOC or APEO

Indoor air quality remains high during and after application.

No Toxic Compounds

Not harmful during production, installation, or occupation.

No Odour

No noticeable smell during application, suitable for occupied spaces.

Low Carbon Emissions

Does not emit ozone-depleting substances during production or construction.

No Radiation

Contains no radioactive materials, completely safe for any environment.

Low Environmental Impact

Uses natural and renewable resources in production process.

No Efflorescence

Prevents powdery salts forming from surplus water on surfaces.

No Polymer

Purely inorganic matrix—not prone to polymer degradation over time.