REVOLUTIONARY DRY-MIX TECHNOLOGIES

POZZOLANA® Pozzolana is positioned to revolutionise the Australian flooring market through the introduction of next-generation mineral-based binder technology. By combining superior technical performance with sustainability and reliable supply, supported by moderate start-up costs, strong industry demand, and clear technical advantages, the company is well positioned for rapid growth and long.

REVOLUTIONARY DRY-MIX TECHNOLOGIES

POZZOLANA® Pozzolana is positioned to revolutionise the Australian flooring market through the introduction of next-generation mineral-based binder technology. By combining superior technical performance with sustainability and reliable supply, supported by moderate start-up costs, strong industry demand, and clear technical advantages, the company is well positioned for rapid growth and long.

REVOLUTIONARY DRY-MIX TECHNOLOGIES

POZZOLANA® Pozzolana is positioned to revolutionise the Australian flooring market through the introduction of next-generation mineral-based binder technology. By combining superior technical performance with sustainability and reliable supply, supported by moderate start-up costs, strong industry demand, and clear technical advantages, the company is well positioned for rapid growth and long.

REVOLUTIONARY DRY-MIX TECHNOLOGIES

POZZOLANA® Pozzolana is positioned to revolutionise the Australian flooring market through the introduction of next-generation mineral-based binder technology. By combining superior technical performance with sustainability and reliable supply, supported by moderate start-up costs, strong industry demand, and clear technical advantages, the company is well positioned for rapid growth and long.

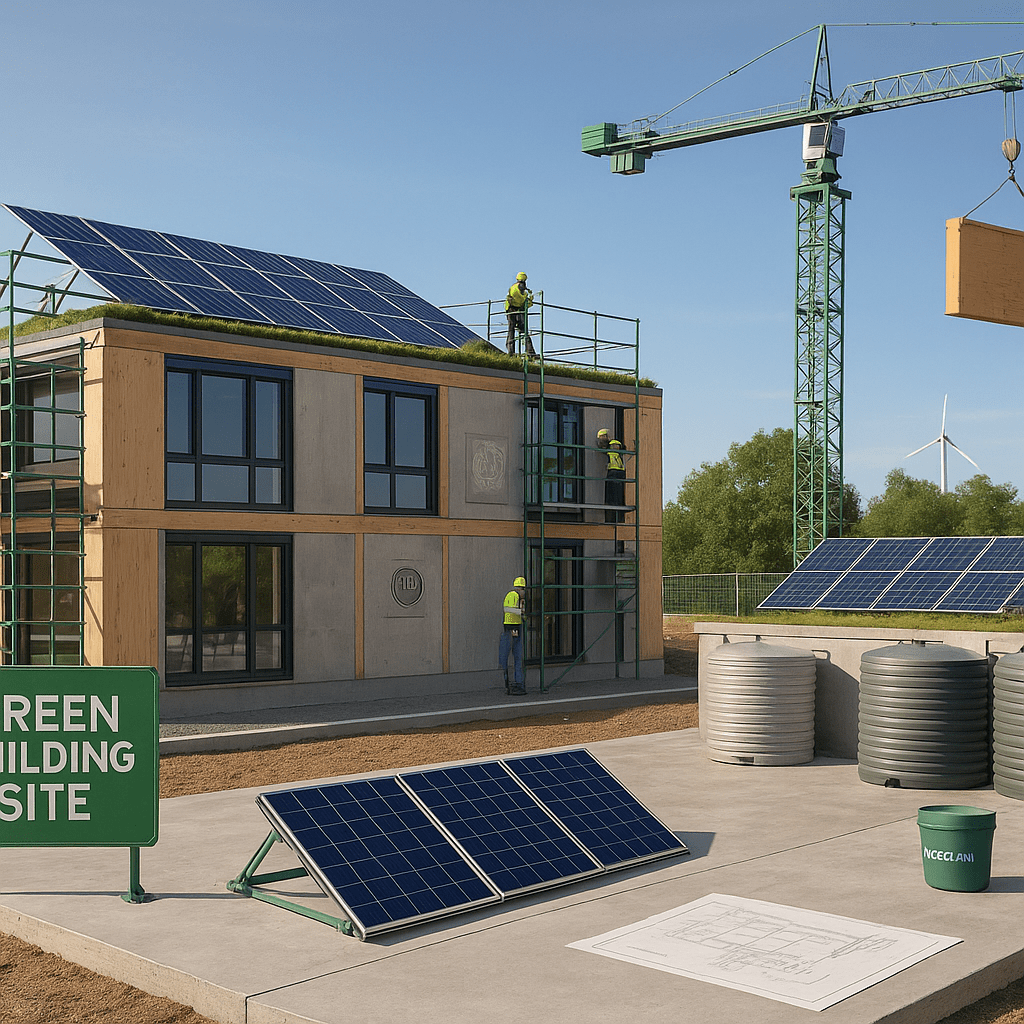

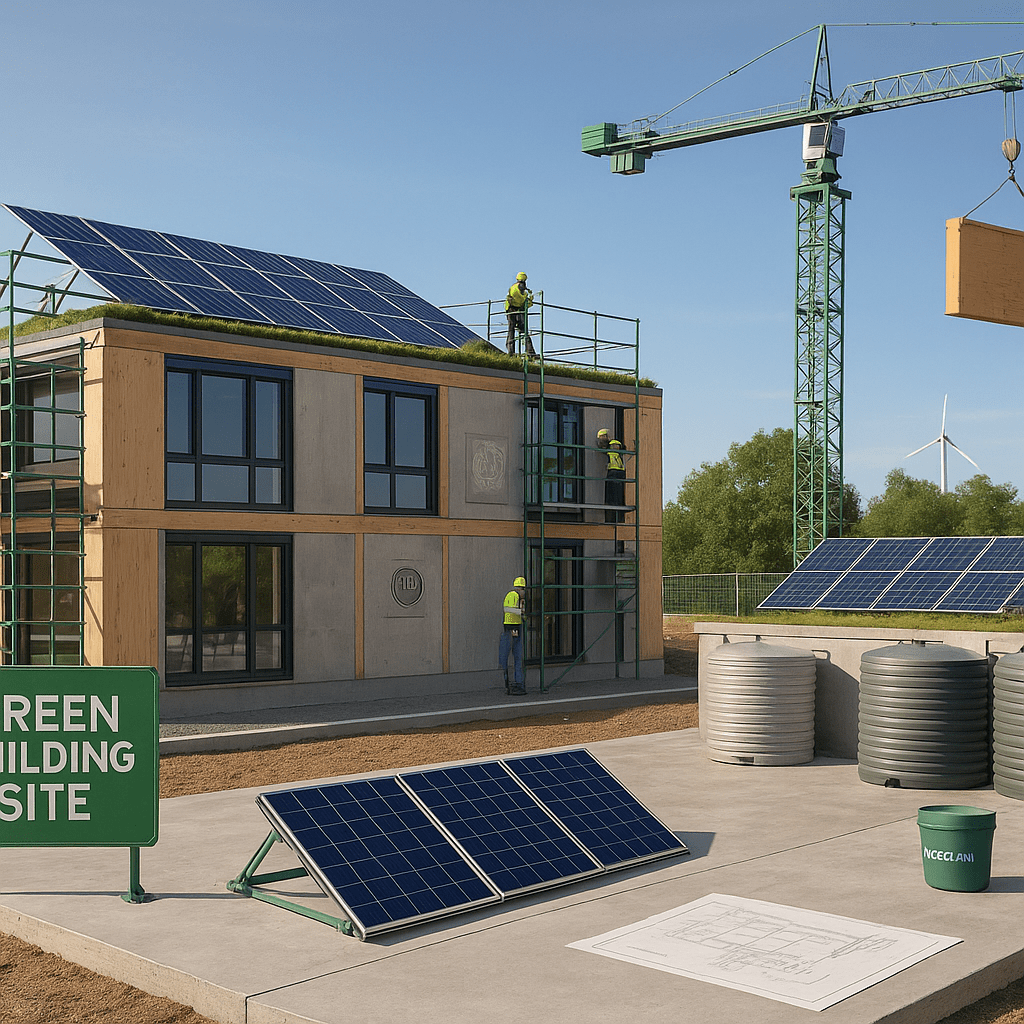

Building the Future of Sustainable Floors

We partner with contractors, architects, and builders to deliver efficient, sustainable, long-lasting floors—combining smart materials, practical know-how, and reliable site support.

Many strands of place-making, environmental stewardship, social equity and economic viability into the creation of places.

Many strands of place-making, environmental stewardship, social equity and economic viability into the creation of places.

Many strands of place-making, environmental stewardship, social equity and economic viability into the creation of places.

Why Pozzolana?

Environmentally friendly

Non-toxic

No allergic potential

100% inorganic material

No VOC or APEO

Low emission (EC1 PLUS)

High flowability

Fast setting and minimises waiting time

Wide range service temperatures resistant to subzero temperatures

Extreme heat and thermal shocks

High abrasion resistance

High abrasion resistance

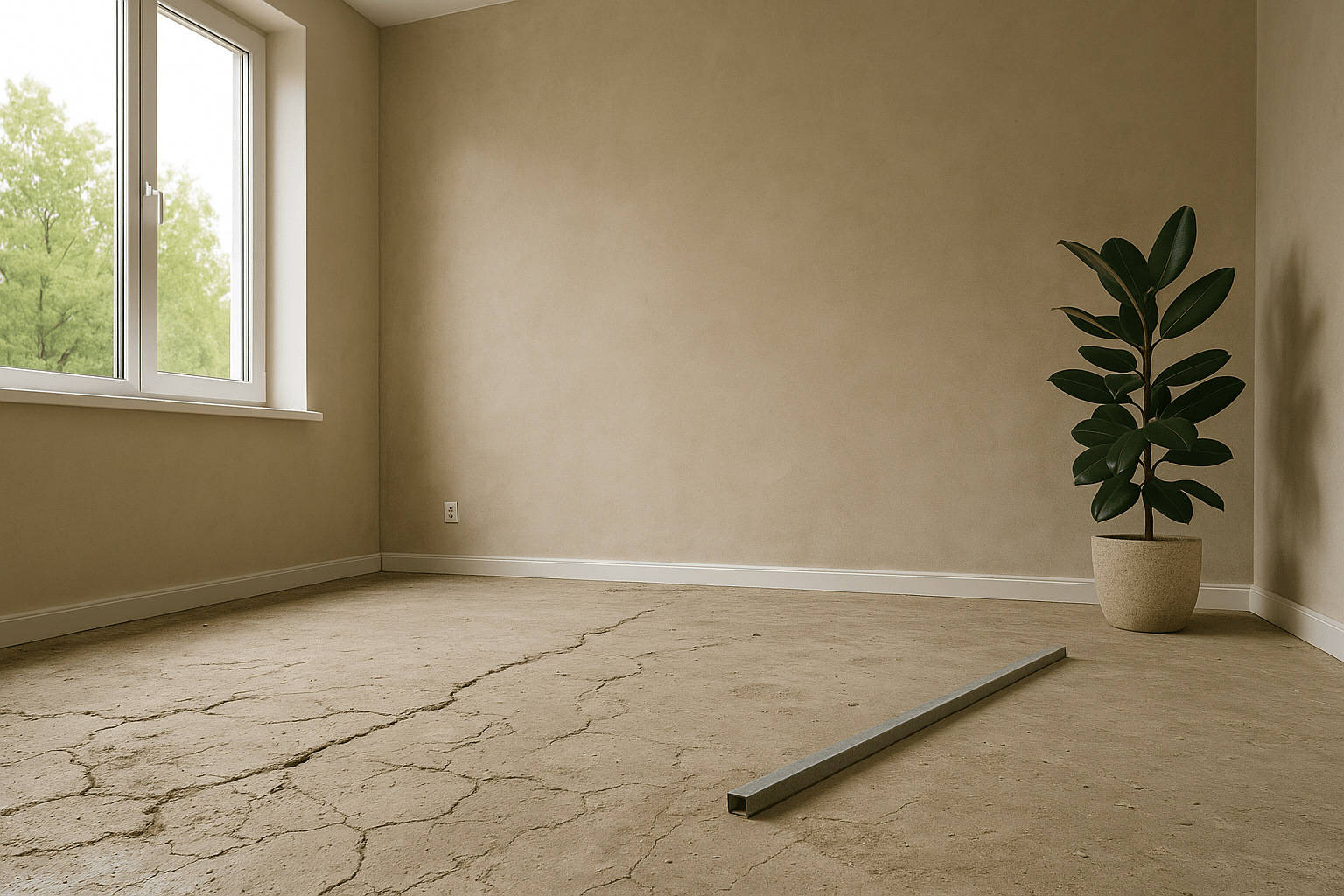

No shrinkage (DIN EN 13454) swelling, natural crazing or cracks.

Our Products

Explore our eco-friendly self-leveling compounds, primers, and accessories—engineered for smooth, durable finishes in commercial, industrial, and residential projects. Every product is low-emission and job-site ready, with clear specs (EPD/SDS) and expert support to help you hit performance and sustainability goals.

200S Self-Leveling Underlayment

Underlayment

700S Decorative Wall Render

Wall Render

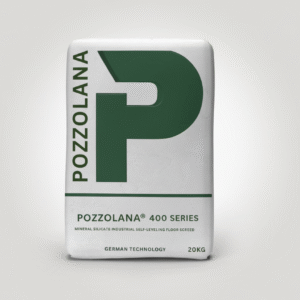

400S Industrial Self-Leveling Compound

Industrial SLC

730S Décor Wall and Floor Render

Wall & Floor Render

500G Terrazzo Grey

Terrazzo Topping

920 SCR Chem Resistance Mortar

Chem-Resistant Mortar

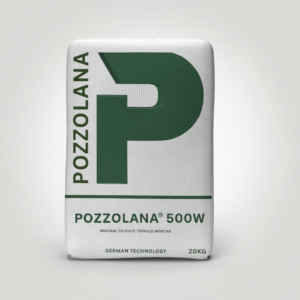

500W Terrazzo White

Terrazzo Topping

935 SLC Hybrid Self-Leveling (35MPa)

Hybrid SLC (35 MPa)

600S Commercial Self-Leveling

Commercial SLC

945 SLC Hybrid Self-Leveling (45MPa)

Hybrid SLC (45 MPa)

212 AVC - Anticrack Underlay

Anti-Crack Underlay

205 MSA 1.5MPa- Stone/Tile Adhesive

Stone/Tile Adhesive

190 PCS - Water-Based PU Sealer

PU Sealer (Water-Based)

198 WIS - Silicone Sealer

Silicone Sealer

Our Portfolio

Explore our eco-friendly self-leveling compounds, primers, and accessories—engineered for smooth, durable finishes in commercial, industrial, and residential projects. Every product is low-emission and job-site ready, with clear specs (EPD/SDS) and expert support to help you hit performance and sustainability goals.

Filter by

- All

- Architecture

- City Marks

- Interior Design

- Residence

Our Process

A simple, spec-to-site workflow that keeps sustainable floor prep predictable, compliant, and on schedule.

Consult &

Scope

Review drawings, performance targets, and sustainability goals. Deliverables: preliminary spec, coverage estimate, EPD/SDS pack.

Choose The Right &

Product

Substrate and moisture testing, compatibility check, and risk review. Deliverables: product/mix recommendation, primer plan, method statement.

Technical &

Support

On-site technical support during pour, QA checks (flow, thickness, temp/RH), and curing guidance. Deliverables: as-applied spec, maintenance guide, LEED/BREEAM documentation.

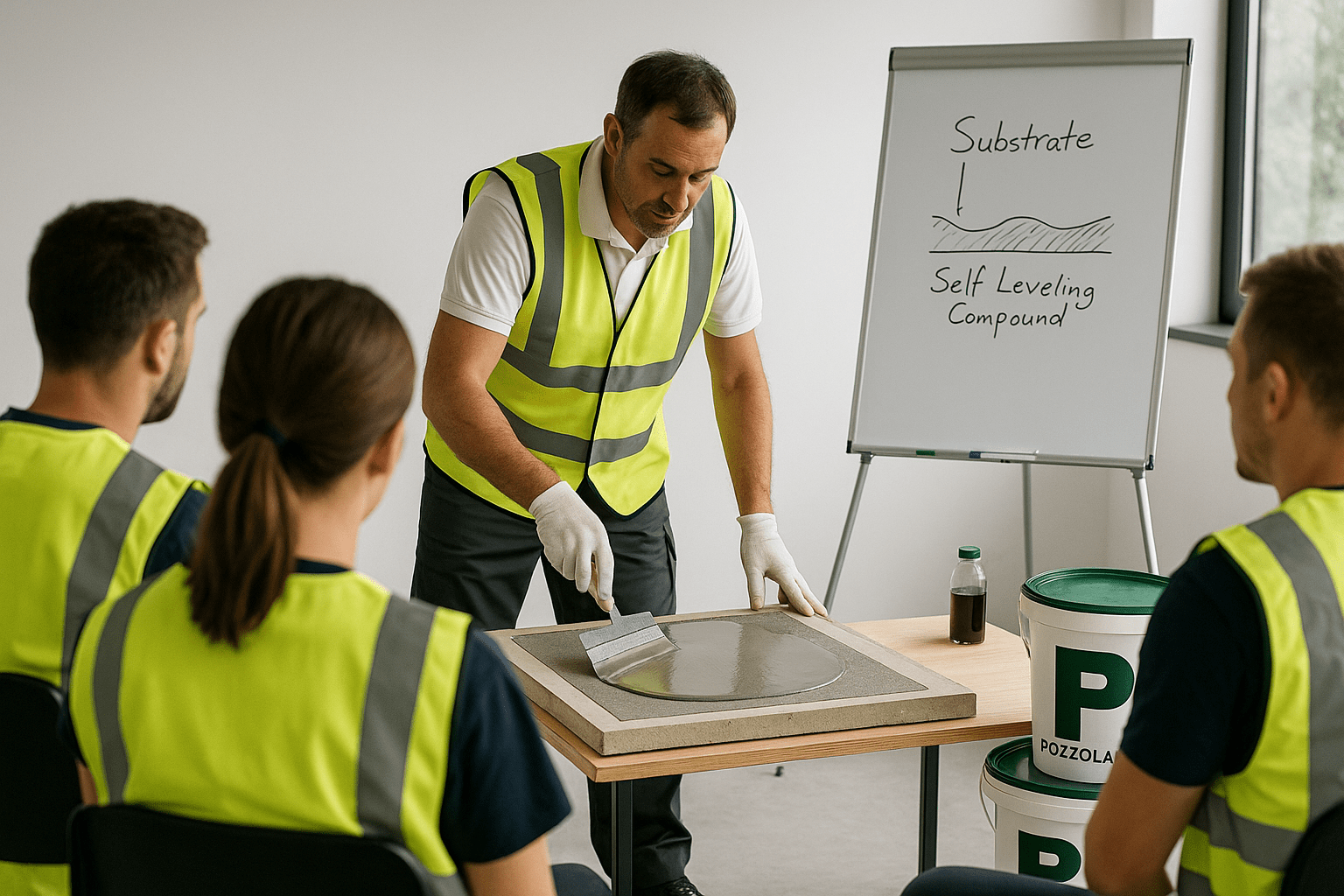

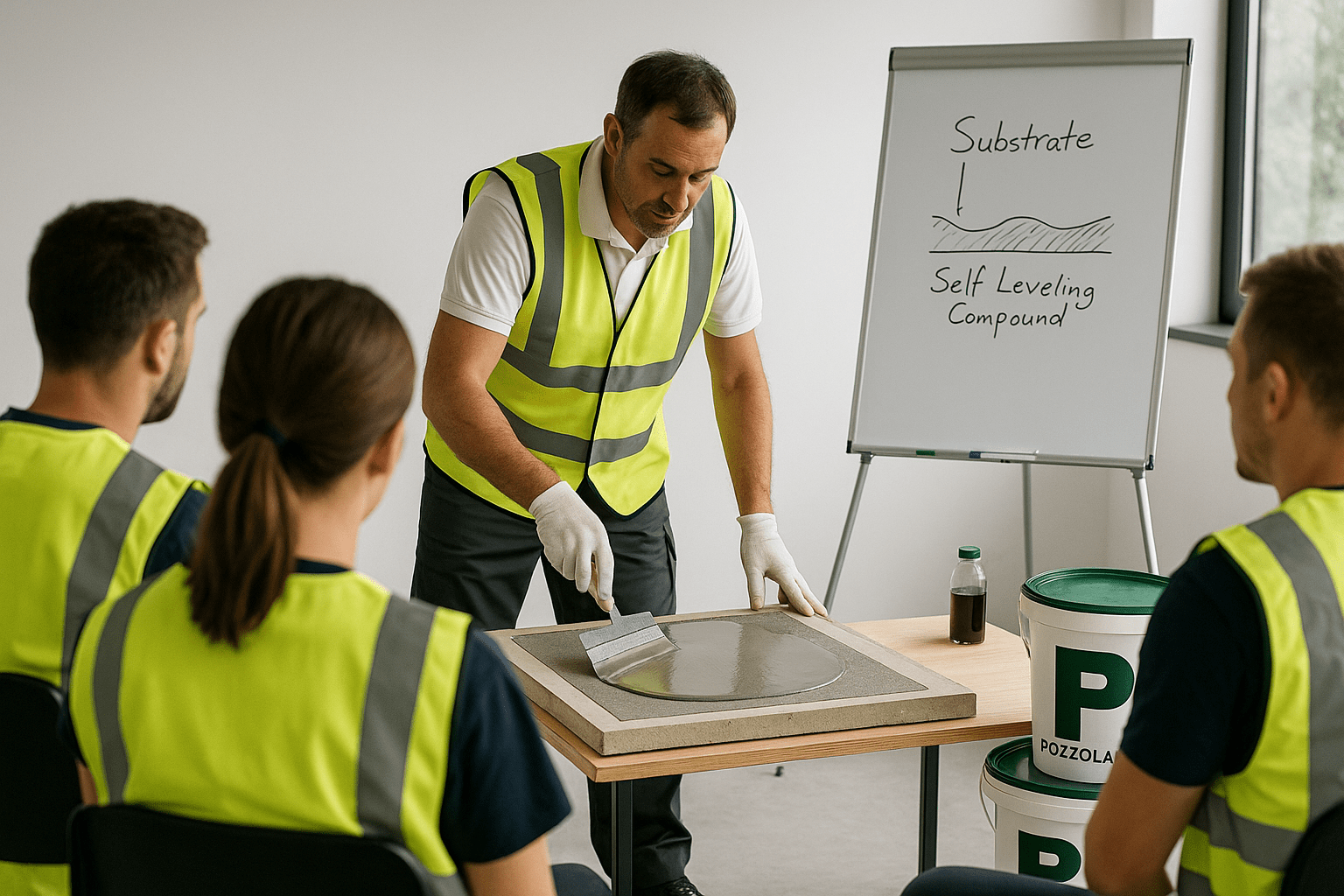

Mock-Up &

Prep

Samples or small-area mock-ups; installer briefing or training; logistics and surface-prep checklist. Deliverables: application guide, schedule, safety/low-VOC plan.

Team Members

Through a unique combination of engineering, construction and design disciplines and expertise.

Why Mineral Silicate Technology

Human-safe chemistry and minimal environmental impact, paired with strong performance.

Safe for humans

- Non-toxic; no allergic potential

- VOC and APEO free

- Does not contain any flammable substances

Environmentally friendly, minimal impact

- Very low energy in production, transportation & application

- Very low carbon footprint & water consumption

- Industrial waste reused; minimized waste footprint

- Up to 100% recyclable; easy maintenance (clean with water)

- Very high durability and sustainability

Very high adhesion

Adheres to many substrates, including smooth surfaces like ceramics and glass.

No shrinkage

No shrinkage or swelling—no shrinkage cracks.

UV resistant

No fading of colours and no flaking.

No allergic potential

Formulated without substances known to cause allergies common in cement- or resin-based systems.

No joints necessary

No joints required on a stable substrate.

High abrasion resistance

Very high abrasion resistance—even 24 hours after application.

Water-vapour permeable

Breathable; allows vapour diffusion through the system.

No efflorescence

Resists efflorescence even in high-moisture, alkaline environments.

VOC & APEO free

Minimizes effects on human health and the environment.

Machine-applied

Compatible with a variety of machines for floors and walls.

Many substrates

Can be applied on weak or moist substrates; suitable over calcium-sulphate and magnesium-carbonate bases.

Chemical & salt resistant

Stable in many chemically aggressive or saline environments.

Burnishable & polishable

Can be burnished or polished for higher sheen.

Temperature-stable

Performs across a wide temperature range; resistant to thermal shocks.

Flexible in application

Adaptable to different application methods and project requirements.

Easy pigmentation

Accepts powder or liquid pigments to create bright colours.

Conventional Problems We Have Avoided

No shrinkage

Cracks due to shrinkage do not occur.

No joints

No saw-cut joints required on stable substrates.

No VOC or APEO

Indoor air quality remains high during and after application.

No toxic compounds

Not harmful during production, installation, or occupation.

No odour

No noticeable smell during application.

Low carbon emissions

Does not emit ozone-depleting substances during production or construction.

No radiation

Contains no radioactive materials.

Low environmental impact

Uses natural and renewable resources.

No efflorescence

Prevents powdery salts forming from surplus water.

No polymer

Purely inorganic matrix—not prone to polymer degradation.

Our Services

Explore our eco-friendly self-leveling compounds, primers, and accessories—engineered for smooth, durable finishes in commercial, industrial, and residential projects. Every product is low-emission and job-site ready, with clear specs (EPD/SDS) and expert support to help you hit performance and sustainability goals.

Self-Leveling Compound Supply

We manufacture and supply eco-conscious self-leveling compounds suitable for a wide variety of substrates and applications — from residential interiors to large-scale commercial projects. Our products are engineered for smooth, crack-resistant finishes with low VOC emissions.

Green Building Consultation

Need help meeting green building standards like LEED or BREEAM? Our team provides expert guidance on how to integrate our sustainable compounds into your project to support environmental certifications and regulatory compliance.

On-Site Technical Support

Our field experts are available for on-site support and application guidance, ensuring optimal results and efficient installation. We help troubleshoot substrate issues, assess moisture levels, and recommend the best preparation methods.

Custom Formulations

For specialized projects, we offer tailored self-leveling compound formulations to meet specific performance, setting time, or environmental requirements — without compromising our eco-friendly core.

Training & Education

We provide training for installers, contractors, and project managers on best practices for applying our self-leveling products in a safe, effective, and environmentally responsible way.

Latest Posts

Interior design is the art and science of enhancing the interiors, sometimes including the exterior.

Building the architecture of the future cities

I think that you should be able to select more than one reason for rating.

Collective Living Challenge In modern design

Success needs hard work. Don’t listen to these ‘get rich quick’ schemes.

Utilizing wood in architecture

I think that you should be able to select more than one reason for rating.

1

Project Analysis

We review drawings and timelines, test substrate flatness and moisture (RH/CM), and confirm compatibility. You get a clear method statement, coverage estimate, and primer plan.

2

Functional Spaces

Solutions for commercial, industrial, and residential areas—engineered for low VOCs, heavy traffic, hygiene zones, and fast turnarounds without sacrificing finish quality.

3

Residence & Condo

Quiet, smooth subfloors ready for tile, vinyl, wood, or epoxy. Low-odour, fast-setting options compatible with underfloor heating and tight renovation schedules.

4

Construction Support

On-site technical help from pour day to close-out: installer briefing, pump/trowel guidance, QA checks (flow, thickness, temp/RH), and documentation for compliance.

Before

Before

After

After

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()